MODIFIED CYLINDER HEADS | |

|

This is a NORTON ES2 cylinder head. The original flanged inlet has been removed and the bore of the inlet tract increased from 27mm to 34mm. This new inlet tract has 15 degrees of downdraught and is designed for a MK2 AMMAL Concentric. The length of the inlet tract can be made to the customers requirements along with any downdraught that is required. |

|

| |

|

This is a view from a different angle that shows the high quality of the workmanship. With this class of finish it could have come straight from the Norton competition shop. |

|

| |

|

This is a Norton 500T cyliner head that has been fitted with special valve seats and valves, the exhaust is 40mm and the inlet is 48mm. It has the 34mm downdraught inlet tract but with a flange fitting. This head is for a customer in Holland who races in club events and the 500T head will fit straight onto his early type barrel. |

|

| |

|

This is a 1947 iron head that I have fitted with a 34mm downdraught inlet tract. This head is for a machine that is used for sprinting and hill climbs, the original 25mm inlet tract was a major restriction to the engines performance until I designed and fitted the new inlet. |

|

| |

|

This is the latest head conversion. It has a smaller exhaust port because the standard ES2 suffers from too large a port. It is fitted with a large inlet valve and seat and has an oval squish band chamber to be used with a flat crown piston. Again the inlet tract is 34mm with 15 degrees of downdraught. This type of head can be machined to fit bore sizes from standard 79mm right up to 90mm. |

|

| |

|

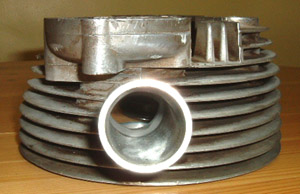

In this shot the barrel has been put in position and you are looking up the bore. This is a good way to visually look at the actual combustion chamber on a finished assembly. This barrel is bored out to 84mm and will be used with a 90mm stroke crank. The 84mm X 90mm engine was a very successfull experiment by Norton during 1939. The three test machines would manage 90 mph with ease and cruise at around 80 mph. This was with rigid frames and girder forks. With the outbreak of World War Two Norton concentrated on the 16H sidevalve millitery machine and after the war there was no money for development and they carried on with the original bore and stroke of 79mm X 100mm. |

|

| |

|

This is a good view of a repaired exhaust port thread. The damaged port is machined out to accept a new threaded insert that is shrunk in a 490 degrees for a permanent repair. The aircraft quality aluminium that I use is far superior to the original material of the cylinder head. |

|

| |

|

The above type of modifications along with replacing missing cooling fins and repairing stripped exhaust ports can be carried out on most makes of cylinder heads. | |