CRANKSHAFTS. STANDARD & SPECIALS | |

|

Crankshaft assemblies can be manufactured in high tensile steel to replace cast iron flywheels for single cylinder machines. Original flywheels can be lightened and re-balanced to the customers requirements or just simply re-built with new Big-End bearings. The assembly in the photo is a short stroke crank for a Norton engine that uses the standard shafts and bolt up big end but is fitted with a caged roller bearing. |

|

| |

|

This is a batch of completed flywheels that are now waiting to have the main shafts pressed in. Once this operation has been completed they can each be balanced to the customers choice of piston before being assembled and trued. They will then be individually assembled into their respective crankases with the correct endfloat set by the use of shims. |

|

| |

|

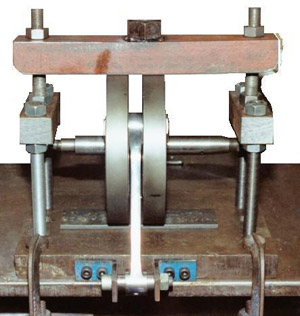

The photo shows a crankshaft bolted down in the jig that has been lightened

by 5lb. It now weighs 19lb and has been re-balanced to 68% for fast road work.

This crank is still the standard long stroke and is capable of 6,000 rpm. |

|

|

| |

|

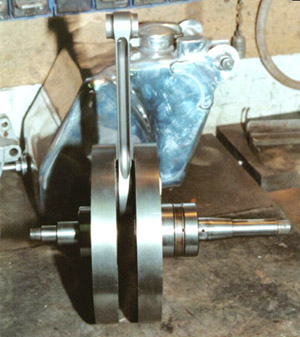

This is a special 90mm stroke crank that is fitted with a Carrillo conecting rod. This is being used with a bore of 84mm to give a capacity of 499cc with the intention of sprinting and hitting 7,000 rpm on a regular basis. |

|

| |

|

This is a three bearing crankshaft from an AJS 650 CSR. As can be seen the balance factor is fully adjustable. The engine suffered very badly from vibration and although the crank was re=balanced the customer required the facility of being able to change the balance factor if required. |

|

| |