ENGINE ASSEMBLY | |

|

All rebuilds are carried out in a dust free enviroment to a very high standard. At this stage the unit is fully assembled to allow the working tolerances to be set up correctly. Crankshaft and camshaft end float, valve to piston clearence and piston ring gaps. The engine assembly is then dismantled and all parts are thoroughly cleaned and checked before the final assembly.

|

|

| |

|

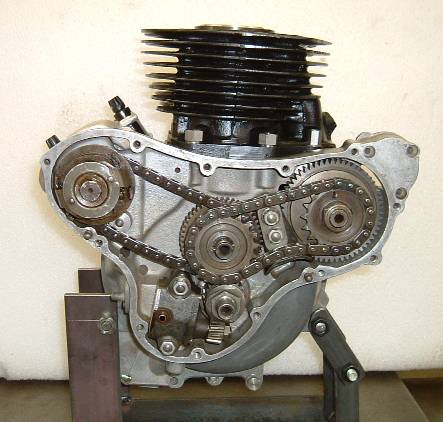

The valve timing on all engines is set with a DTI clock in realationship with the crankshaft to ensure perfect valve timing.

|

|

| |

|

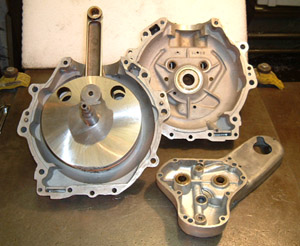

The end float on the crankshaft is also set with the aid of a DTI clock while at the same time ensuring that the connecting rod is maintaining a central position in the crankcase mouth.

|

|

| |

|

This 1955 Norton Dominator was rescued from the living room of an old gentleman were it had been completely dismantled and left in a box for 25 years. The Norton is now back on the road where it runs and looks as good as it did when it was a new machine.

|

|

| |

|

This Triumph 1960 T110 is another machine that had been dismantled and stored for many years. The head and barrels had been removed and the crankshaft and main bearings were covered in rust. The crankshaft was so bad that I had to put it in the gritblaster to remove all the rust from the flywheel. This machine is also back on the road and resembles a new machine.

|

|

| |

|

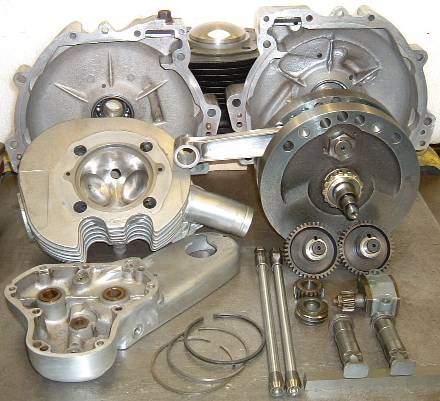

This is a complete engine prior to assembly, all the parts have been cleaned and are ready for going together. The crankshaft has allready been fitted once to set the endfloat. Many of the parts you see here have been lightened and balanced to improve the overall performance of the finished unit. If you look closely you will see that the cylinder head has been fitted with a 34mm downdraught inlet tract.

|

|

| |